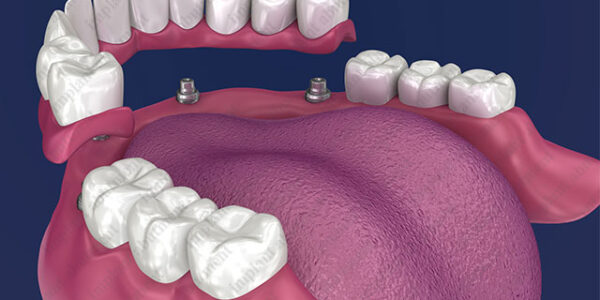

The multi-unit restoration

The implementation of multi-unit abutments in a partial-arch or full-arch restoration provide multiple advantages over cement-retained restorations, restorations that employ classic abutments, and restorations that connect the prosthesis directly to the implant. Through the use of multi-unit abutments, varying angles and heights of each implant along the jaw can be corrected to create a universal height and orientation of the abutments that allows the prosthesis to sit evenly over the arch. The dental professional’s choice of collar height and angulation of each multi-unit abutment within the full-arch restoration should facilitate proper seating of the prosthesis over the placed abutments. When properly seated, the prosthesis’ stability is maximized and force exerted on the restoration is distributed evenly, which allows for optimal functionality and minimized risk of loosening. Multi-unit abutments are indicated for use in both partially and fully edentulous patients, and are often used for All-on-X (All-on-4, All-on-6, and All-on-8) restorations.

Differentiating between the market’s top multi-unit systems

Several of the market’s leading implant brands have developed multi-unit systems that are highly regarded across the dental implant industry. It is important that before selecting a system, dental professionals ensure that the brand they choose is compatible with the implant system they work with.

What distinguishes one multi-unit system from another?

The two main differences to take note of between multi-unit systems are the shape of the cone and the miniscrew. The upper part of the implant abutment cone can vary in diameter from one system to the next, while the miniscrew can vary in diameter to accommodate different platform widths. These slight nuances in multi-unit abutment geometry can determine the compatibility or lack thereof between an implant system and multi-unit abutment. It is therefore important that, before selecting a multi-unit abutment, dental professionals verify that the geometry of the multi-unit system they are interested in is compatible with their in-house implant system.

How multi-unit components can affect the quality of the system

The single-piece versus two-piece angled abutment

It is important to take note of a multi-unit abutment’s style and quality. While elements such as base material used and fabrication procedures are always important to understand from each brand to ensure the highest quality is being used in every step of the production process, other factors such as style are important to consider. This is most important with regard to angled multi-unit abutments, as there are two distinct styles: single-piece and two-piece angled abutments.

The manufacturing of a single-piece angulated abutment is no simple feat. It is a complex procedure that has a simple solution: create a base and then a screw-on multi-unit — these two pieces together form the two-piece abutment. But the caveat is a big one. Compared to the single-piece abutment, the two-piece abutment has a greater tendency for instability and screw-loosening, which can inevitably cause problems with the restoration further down the road. Though more difficult to produce, the single-piece abutment is a sturdier unit with a much greater likelihood of long-term success.

Multi-unit miniscrew diameter

Put simply, wider-diameter screws make for a stronger restoration. By using a miniscrew with a wider diameter, the abutment is more stable and at a lower risk of breakage than in a system with a narrower screw.

Nobel® multi-unit abutments

Nobel Biocare® was one of the first and is still one of the most well-known multi-unit systems available to the market. Developed in 2000, it is considered an industry standard for multi-unit abutment design and has served as a reference for many subsequent companies aiming to design and manufacture multi-units. It was also with the introduction of the Nobel® multi-unit abutment impression coping that taking impressions for final restoration design was made easier and more accurate. Let’s take a look at the elements of the Nobel® multi-unit abutment that set it apart from day one and have maintained its popularity over the decades.

The cone of Nobel®’s multi-unit abutment features a short design that is intended for restorations with limited or minimal interocclusal space. The cone features a wide shoulder, which is meant to facilitate an easy positioning and insertion of the prosthesis over the abutment. Nobel®’s cone comes in three angulation options to accommodate multiple scenarios and ranges of soft-tissue anatomy: straight, 17° and 30°.

The Nobel® multi-unit system has compatibility with a wide range of miniscrews for a range of restorative scenarios. Miniscrews for narrow, regular and wide platforms can be used with the Nobel® multi-unit system.

Edison Medical™ multi-unit abutments

Edison Medical™ is one of the rising stars of the dental implant market, manufacturing and distributing their products via their online marketplace. Founded in 2010, Germany-based Edison Medical™ has undergone a massive expansion in recent years, which has included joining forces with Ritter Implants® and establishing a logistics center in the US. Edison Medical™ has gained popularity in large part due to its wide range of products that are compatible with more than 70 of the implant market’s leading brands.

Edison Medical offers a classic multi-unit abutment whose cone is available in three angulation options (straight, 17° and 30°) and which features an M1.4 miniscrew. Their own patent-pending Clicq™ line is available in the same three angulation options, but features a wider-diameter M1.6 screw to facilitate a more stable connection.

Zimmer® multi-unit abutments

The Zimmer® multi-unit abutment has a tapered design with a conical screw-receiving platform that extends through the tissue. Both Zimmer®’s straight and angled multi-unit abutments feature a 4.5-mm conical platform. With a range of cuff heights and implant platforms, Zimmer® offers a range of abutment options to accommodate most restorative scenarios. Zimmer®’s tapered abutments are available as straight abutments, or with an angulation of 15° or 30°. For restorations in which occlusal space is limited, Zimmer®’s 1.2-mm low-profile abutment is an ideal solution, and the 15° cone taper helps to establish the framework that can achieve a passive fit.

Implant Direct® multi-unit abutments

Implant Direct® was one of the first implant manufacturers to offer a web-based business to their dental clients. Implant Direct® has two implant lines compatible with multi-unit systems: Legacy™ and InterActive™. Both implant systems are available with either a straight or 30°-angled cone.

Dentium® multi-unit abutments

Dentium® is a South Korean dental implant company that was founded in 2000, with its claim to fame being its original success with SLA (sand blasting with large grits and acid-etching) surface treatment on dental implant components.

Dentium®’s SuperLine™ and Implantium™ implant lines are both compatible with multi-unit systems. The cone for Dentium® multi-unit abutments is available in straight option, or with 15° or 30° of angulation. Straight abutments feature a 1.8mm-diameter screw, while angled abutments are compatible with a 2.0mm-diameter screw.

Astra® multi-unit abutments

The Astra® Tech implant system is a product of Dentsply Sirona® and is another leader in multi-unit systems. Dentsply Sirona® is one of the world’s largest dental product manufacturers and is well-known for its line of Astra® implants. Astra® multi-unit abutments come in multiple cone height options, and angulation options include straight, 17° or 30°.

How to choose the right multi-unit system

Notwithstanding the impressiveness of many of the mentioned multi-unit systems, some of them are the most expensive on the market. When there were few options, having a choice was not as much of a luxury as it is today. In today’s market that has a lot of high-quality competition rising up, the question of whether it is worth it to spend double the money on a product that can be purchased with the same quality or better elsewhere for half the price is indeed one to mull over. That said, no matter the choice of company, a purchase should never sacrifice quality. Make sure that if you choose a company that is offering a product for less, that the company is still making an excellent-quality product. The highest level of precision is a must in restoration systems, and any wavering of accuracy can result in unwanted problems down the road.