How Does the Dental Torque Wrench Improve Restoration Success?

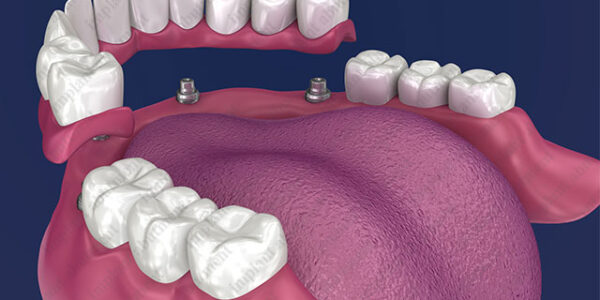

The dental restoration process and its success depend on an array of factors. It is not only the components of the restoration such as the dental implant, abutment, and prosthetic tooth that need to be taken into consideration. The tools and instruments that are used to carry out the surgery and subsequent procedures are also incredibly important. Clinical stability of an implant is determined by many factors, and one way that it is measured at the time of surgery is with insertional torque measurements. The torque of the implant in the jawbone must be just right — not too loose and not too tight — to avoid excessive force in either direction and resulting risk of complications such as breakage or loosening.

The dental torque wrench for a perfect fit

To measure the torque of the implant in the jawbone during stage II surgery, clinicians use dental torque wrenches. A reverse torque value of around 30-40 N/cm indicates to the operating doctor that the peri-implant cells have undergone the necessary osseointegration required to facilitate a healthy and stable restoration. Insertional torque measurement during implant placement is only one of many uses that the dental torque wrench has. The dental torque wrench can be used in any aspect of placement during the restoration procedure’s stages to apply specific torque when securing a component into place.

The dental torque wrench’s role in abutment stability

The dental abutment serves as the connection between the implant and the prosthesis. It is imperative that the abutment remain fixed without even the slightest micromovement to ensure long-term restoration success. When using a dental torque wrench, dental professionals are able to determine the necessary torque required for the specific restorative scenario, set that value on the torque wrench, and tighten the abutment screw to that precise value (accuracy typically falls within 10% of the target value). Over-tightening the torque can lead to damage or breakage of the abutment or implant, whereas an abutment that is too loose can result in micromovements or screw loosening, ultimately resulting in restoration failure. As each abutment and implant scenario can vary, clinicians usually combine the manufacturer’s torque recommendations with their expertise to determine the specific target torque value to be used.

The most common dental torque wrench types

Several types of dental torque wrenches exist, with the two most popular being the toggle torque wrench (friction-style) and beam torque wrench (spring-style). The beam torque wrench is coveted for its higher consistency over the toggle torque wrench in general calibration. The most precise beam torque wrenches feature a dial indicator, allowing a Tare torque to be set.

The clinician’s responsibility: investing in a great torque wrench

For many it goes without saying, but it is always important to reiterate the importance of investing in high quality products that are sourced from reliable manufacturers. Excellent material quality, production processes, and proper certification of any dental implant component, tool or instrument provides the assurance that both dental professionals and patients should expect to rely on. Gambling with these necessary aspects of quality to save money is never worth it in the long run, as the entire restoration can be jeopardized. A new wave of e-commerce dental implant suppliers have established themselves in the online marketplace, offering extremely high quality products at significantly reduced prices. These suppliers, the best of which are also carrying out the manufacturing of their products, are a sound alternative to the high-end prices that are often spent when sourcing through local distributors and big-name manufacturers.